Dual

Carburetor Synchronization

Rolls Royce Silver Cloud and Bentley S I

July 20, 2002 - Saratoga, CA (click for event Pix)

Jim Weager Presiding Technically

Hosts - Barbara & Austin Kilburn

click

on

the

title for PAGES:

TOOL

SUGGESTIONS…………………………………….…

2

A-

PRELIMINARY DISASSEMBLY………………………..

3

B-

CHECKING EQUAL

NEEDLE POSITION………….…

4

C-

THROTTLE PLATE

SYNCHRONIZATION…………….

5

D-

CARBURETOR SUCTION

CHAMBER ASSEMBLY…

6

E-

SETTING THROTTLE

LEVER CLEARANCE………...

7

F-

SYNCHRONIZATION OF

THE CARBURETORS……..

8

G-

IDLE SPEED

ADJUSTMENT……………………………

10

H-

MIXTURE ADJUSTMENT;

ROUGH…………………… 10

H-

MIXTURE ADJUSTMENT; FINE…………………………

11

I-

FINAL CHECK……………………………………………..11

J-

SETTING THE

FAST IDLE

CAM CLEARANCE……...11

K- FINAL ASSEMBLY……………………………………….. 12

THE STICKING PISTON…………………………………….. 12

Prior to attempting the

following procedure, it is assumed that the engine and the ignition system,

including the fuel pump, fuel filter and air filter are all in good working

order.

After the removal of the Air

Cleaner and Cold Air Runner, if you are absolutely certain that the needle

position is the same on both carburetors and positively sure that both throttle

plates are in synch with each other, you may begin at Step E- Setting Throttle

Lever Clearance.

Gasket (1) Choke Body to Cold Air Runner

Gaskets

(2) Cold Air Runner to Carburetor

Note: The use of the old gaskets is certainly

permissible. The key here is that

they are in good condition. Small

air leaks due to poor gaskets are not fatal because it represents an air leak

prior to the introduction of the fuel mixture.

A major cold air leak could create an audible hissing sound, weaken the

effect of the air cleaner, and most certainly implies maintenance practices

inconsistent with your PMC.

Note: The short length of

the tools, while not essential, will assist in the application of the tools in

tight places.

Screw Driver

7/16th inch box and open end wrench (suggest

4 inch length)

1/2 inch box and open end wrench (suggest 5 inch length)

13/16th inch box, open end or socket

9/32nd inch box and open end wrench (suggest 4 inch length)

Feeler Gauge (.0187 in.-.020 in. & .098 in.)

Steel Ruler, 6 in.

Putty Knife 1 inch or narrower

UNI-SYN

™ (flow gauge)*

Tachometer

Two (2) Strips of Typing Paper 1/4 in. x 6 in.

Fender Cover

Strong Box or Stool to stand on

*UNI-SYN

™ may be purchased from

Performance Products 1.800.423.3173. www.performanceproducts.com

$28.95

or

other performance or sports car supply source.

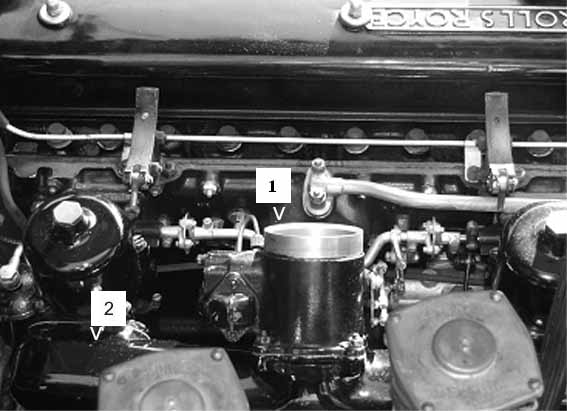

1.

Remove the air cleaner assembly from the Choke Body (Fig. A)

Caution:

Be careful in the following steps not to drop any nuts, lock washers or screws.

2. Remove the 4, 1/2 in. nuts and lock washers from the studs of the Cold Air

Runner

attached to the Carburetor Intake Throats.

3. Remove the 4, 7/16th in. nuts and lock washers from the studs of the Cold Air

Runner

attached to the Choke Body.

4. Remove the Cold Air Runner from the engine.

Note:

Be careful not to kink the vacuum tube or bend the linkage.

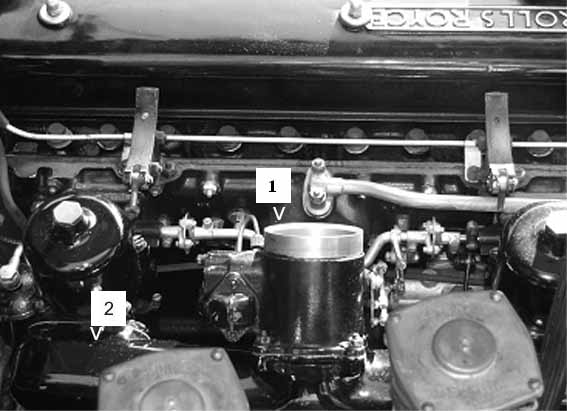

1. With a 13/16th in. wrench loosen and remove the Hydraulic Dampers from the

Piston Chambers. Be careful to note which damper belongs to which chamber. (Fig. B)

checking to see

that it moves freely and bottoms to the seat without binding. This will serve as a benchmark when performing step D-1.

(Fig. C)

If binding is present, go to THE STICKING PISTON found on the last page of this manual.

3. Remove the 4 screws which attach the Suction Chambers to the body of the Carburetor.

Be

careful when removing the chamber from the Carburetor Body.

There is a long spring inside the chamber at the end of which is a

perforated conical washer. (Fig. D)

Keep the correct chamber and spring/washer

with the correct damper and remember to which carburetor

body they belong.

4. Being careful not to apply side pressure, lift the Piston straight up out of the

Needle Jet. (Any side motion during this procedure could bend the Needle or damage the Needle Jet.)

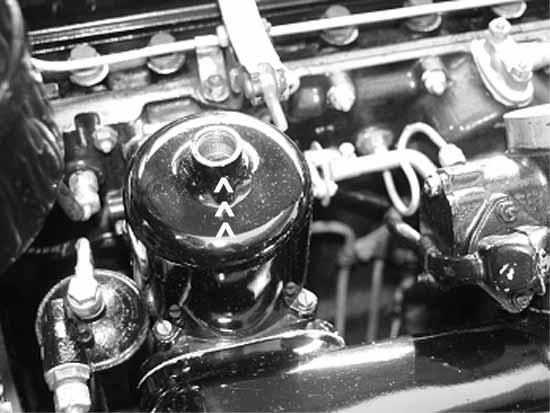

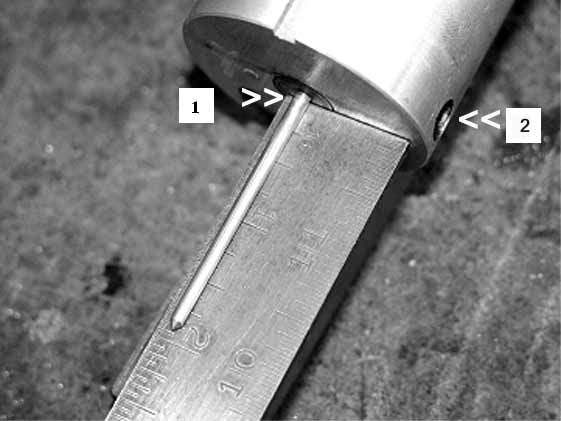

5. With the Steel Ruler, check to see that each needle extends the same distance

from the piston skirt. If not, adjust one of the needles to equal the other. This

can be achieved by loosening the set screw located on the side of the piston

skirt. Hint:

In most cases there is a ring groove cut into the shaft of the needle that acts

as a

visual assurance of proper positioning of the needle.

(Fig. E)

6. Check to be sure the Piston and the inner walls of the Suction Chamber are

free from heavy

carbon deposits. If cleaning

is in order, use carburetor cleaner or lacquer thinner and a soft rag. Under no circumstance

should you use steel wool or sandpaper on these surfaces. Proper tolerance

between piston and chamber is critical.

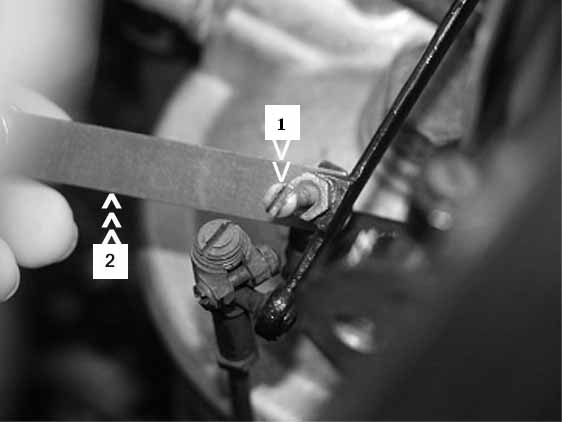

Fig.

E Confirming

length of needle extension

1. Ring Groove location 2. Needle Set Screw

C-

THROTTLE PLATE SYNCHRONIZATION

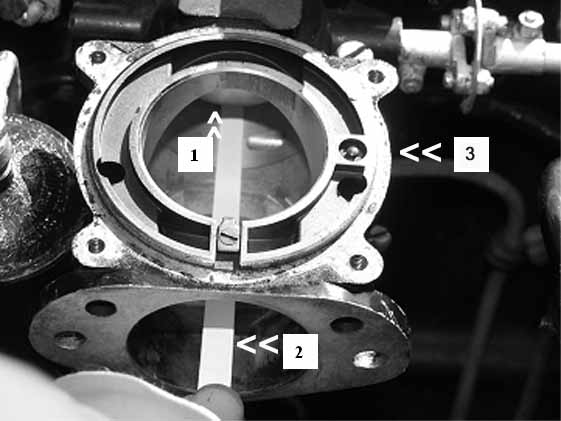

1.

Throttle Plate 2. Paper Strip

3. Lift Pin

Section D, Carburetor Suction Chamber Assembly.

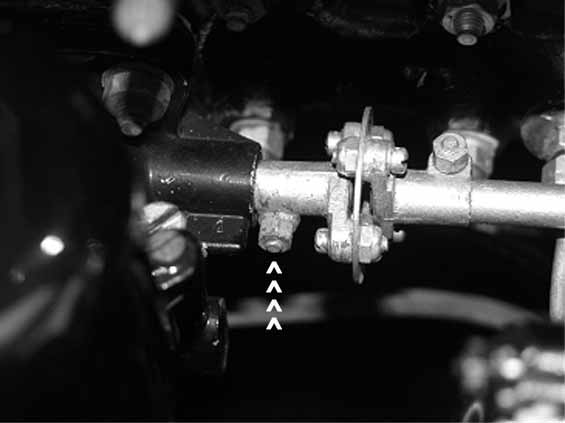

3. Loosen the Pinch Bolts that are adjacent to the flexible couplings. Using your finger, gently push the throttle plate in each carburetor until it is closed. Retighten the Pinch Bolts. (Fig. G) Again try the test in Step 2.

four

screws which secure the Suction Chambers to the body of the Carburetor.

With the screws still loose, place a finger into the carburetor throat

and move the piston up and down (Fig. C),

checking to see that it moves freely and bottoms to the seat with out binding. While repeatedly moving the piston up and down, snug up one

screw and then the screw across from the first screw, continue the

tightening in a crisscross fashion until all are snug.

Check one more time for free piston movement.

Then repeat the same procedure on the second carburetor.

If binding occurs, wiggling the chambers around the axis of the mounting

screws, with the screws softly seated, should fix the problem. Note: If the pistons moved freely in step B-2, the lack of free movement

at this point is likely caused by play between the mounting screws and the

mounting holes in the flanges at the base of the Suction Chambers.

Should the wiggling of the Suction Chambers around the axis of the

mounting screws not solve the problem, you will have to check to see if you

might have accidentally bent the Needles in the handling process.

E- SETTING THROTTLE LEVER CLEARANCE

1. With the Throttle Stop Adjusting screw backed off from the Throttle Stop, place a

.0187 in.- .020 in. feeler gauge between the Throttle Stop and the tip of the

Throttle Stop

Adjusting Screw. Turn the Throttle

Stop Adjusting Screw in until it touches the feeler gauge.

(Fig. H)

The following procedures employ the use of the UNI-SYN ™ (flow gauge)

F-

SYNCHRONIZATION OF THE CARBURETORS

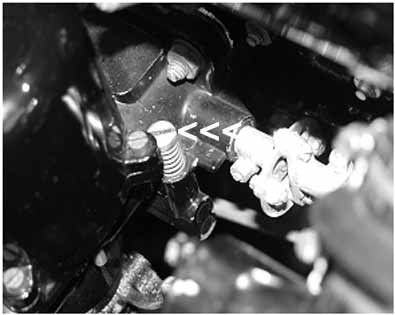

1.

Check to be certain that the Fast Idle Cam is disengaged from the Fast

Idle Set Screw. (Fig.

I)

2.

Turn in both of the Slow Running Adjusting Screws until they stop.

Now back the Slow Running Adjusting Screws out 2 turns. (Fig.

J)

3. Start the engine and hold the UNI-SYN ™ (flow gauge) against the intake bore of one carburetor. Note the position of the “pea” in the site glass of the flow gauge. Now place the flow gauge against the intake bore of the other carburetor and turn its Slow Running Screw in or out until the “pea” in the site glass is in the same position as on the previous carburetor. The carburetors are now synchronized. (Fig. K)

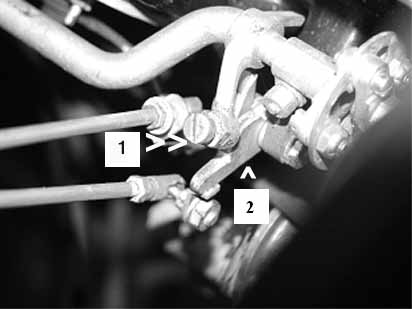

Fig. I

1.

Set Screw 2.

Fast Idle Cam

Fig.

J Slow

Running Adjustment

Fig.

K

Applying the UNI-SYN ™

The

Indicator Pea

Hint:

If the engine refuses to idle smoothly,

engage the Fast Idle Cam against the Set Screw one or two steps until the engine

is running smoothly. Let the engine continue to run until it has reached normal

operating temperature. Then once

again disengage the Fast Idle Cam from the Set Screw.

4. Attach the

Tachometer.

Screw

(to reduce idle speed), or turning out the Slow Running Adjustment Screw (to

increase the idle speed). Idle

Speed for Silver Cloud I and S 1 is 400 to 425 r.p.m. Remember, you are dealing

with two carburetors that both contribute to the idle speed on an individual

basis. When you turn one Slow

Running Screw in or out, you must turn the other Carburetor’s Slow Running

Screw the same amount. Make your

adjustments in small increments. (Fig. J)

Note: If you set the idle speed too high, by turning out the Slow Running Screws too far, the carburetors will whistle at speed.

1.

With the Fast Idle Cam still off the Set Screw (disengaged) and the

Tachometer still functioning, turn one of the Mixture Adjustment Screws out

until there is a change in the idle speed (it should drop in r.p.m.).

This is a lean mixture. (Fig. L)

2. Raise the engine speed for a few moments by lifting the Throttle Lever. This will

help to keep the spark plugs from fouling. This should be done periodically while

you

are executing the Mixture Adjustment.

3. Turn the Mixture Adjustment Screw in a half turn at a time until the engine is

running smoother.

4. Repeat the same process on the second carburetor.

Note: At this point the engine may be running nicely but the mixture must be tested to be sure it is correct for each carburetor.

5.

Lift the Mixture Adjusting Screw with your fingers about 1/16th

inch and hold

that position off the stop. If the mixture for that carburetor is correct, the

r.p.m. will increase slightly and then settle to the original speed.

If the r.p.m. drops and stays there the mixture is too lean.

If the r.p.m. increases and stays at that level, the mixture is too rich.

Alternate

Methode: Under each Suction Chamber is a Lift Pin. It is located on the right side of each carburetor. (Fig. F

No. 2) Push the Lift Pin up about

1/16th inch and hold as in Step 4.

The Lift Pin on the rear carburetor is easy to push with your finger. The

Lift Pin on the front carburetor is very difficult to push because of the Float

Bowl location. But it can be done.

Idle Speed for

Silver Cloud I and S I is 400 to

425 r.p.m.

For vehicles fitted with air conditioning, you may wish to increase

the idle speed to 550-600 r.p.m.

Note:

With the carburetors properly in synch, slow acceleration should yield smooth

response from the engine. No

shudder should be present.

J-

SETTING THE FAST IDLE CAM CLEARANCE

the Fast Idle Cam. Place a .098 in. feeler gauge between the Cam and the

Set

Screw. Turn the Set Screw in until

it touches the feeler gauge. (Fig.

M)

1.

Place a liberal coating of petroleum jelly or spray dry silicon on both

sides of the new gaskets. This will

allow disassembly at a later time with no damage to the gasket material.

2.

Replace the Cold Air Runner.

3.

Replace the Air Cleaner Assembly.

A sticking piston may be indicated by one or more of the following:

A. Stalling

B. Poor Slow Running

C. Lack of Power

D.

Abnormally High Fuel Consumption

A sticking piston, one which does not move

freely up and down, may be caused by one or more of the following maladies:

1. Carbon build up on the sides of the Piston Assembly

a. Remove the Suction Chamber as described in B- 3.

b. Follow the steps B- 4. and B- 6.

c.

If no carbon build is noted go to Step 2.

2. Fowled Needle

a. Lower the Jet by pulling up on the Mixture Lever which is attached to

the Mixture Adjusting Screw (Fig. L). If the binding goes away, the problem lies between the needle and the seat.

b. Centralize the Main Jet. The procedure is too involved to describe here. Refer to “Work Shop Manual for the Rolls-Royce Silver Cloud”, page K14, “Main Jet- to centralize”

3. Bent Needle

a. Loosen the Set Screw as described in B- 5.

b. Follow the steps as described in the “Note” in D- 1

Other PMC Attending (click on any picture to enlarge it)